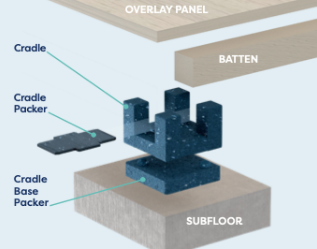

How the rubber crumb cradle is used

See below a short animation of how our Rubber Crumb Cradles are used, whether that be for Raised Acoustic, Sports Flooring or External Decking.

for raised acoustic, sports flooring and external deckingRubber Crumb Cradles are adaptive, eco-friendly and used extensively in new build, refurbishment and conversion projects. This versatile system provides quick and precise on-site levelling to achieve a wide range of finished floor heights.

Why Rubber Crumb Cradles?

Quick installation and long-lasting performance

Sonixx® Rubber Crumb Cradles offer rapid installation and exceptional, long-lasting performance. Manufactured using recycled rubber crumb, these cradles and base packers can be overlaid with chipboard, plywood, cement particle board or hardwood to produce premier acoustic and sports floors, which can accommodate a diverse range of floor coverings.

Environmentally Friendly

All of the rubber crumb in our cradles is made from used vehicle tyres, ensuring we only use materials that are 100% recycled. They are eco-friendly, durable and come with a 60 year guarantee from date of installation.

Acoustic Performance – 28dB (ΔLw)

The acoustic cradles provide outstanding performance in reducing both impact and airborne sound. As rubber crumb does not deteriorate, Sonixx Rubber Crumb Cradles provide long-lasting and superior acoustic performance.

See below a short animation of how our Rubber Crumb Cradles are used, whether that be for Raised Acoustic, Sports Flooring or External Decking.

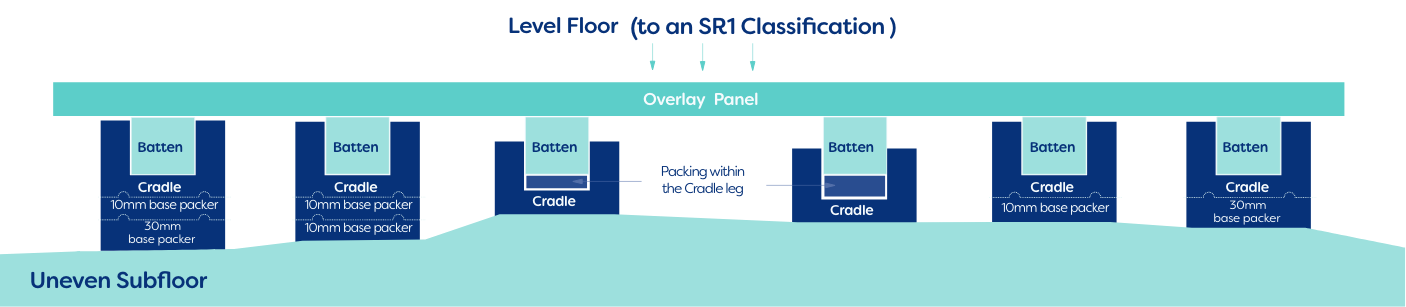

Easy Levelling

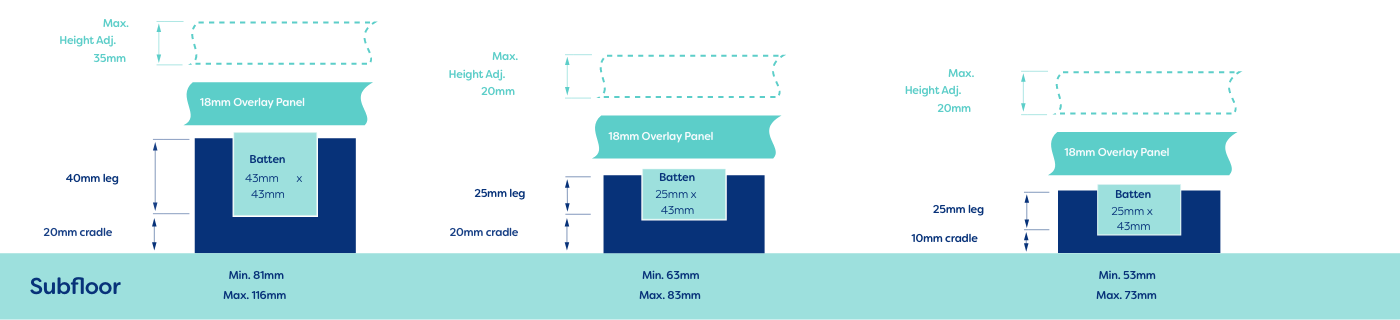

The cradles enable quick and simple levelling of uneven subfloors, through the use of 2mm and 5mm cradle packers positioned

within the cradle legs and below the battens. Additional levelling can be achieved via 10mm and 30mm cradle base packers.

Versatile System

As the cradles are placed directly on the subfloor, no levelling screeds are required. This eliminates the need for wet trades, thereby significantly reducing preparation time and installation costs, as well as streamlining programming and on-site processes. The versatility of the system allows for a wide range of finished floor heights to be achieved.

Acoustic Performance – 28dB (ΔLw)

Rubber Crumb Cradles can be used across a multitude of projects, such as:

Rubber Crumb Cradles which can be used in the following application

For further information fill out our enquiry form or email sonixx@interfloor.com

Sonixx® specialist acoustic underlays significantly reduce sound transmission and have the durability and resilience to remain in situ for decades.